Perfect film production with electrostatic charge close to zero

Producing and converting film can be very critical due to too high levels of static charge. Undesired discharges on the film or to the surrounding can damage the film.

The worst part is that these defects only become visible during further processing.

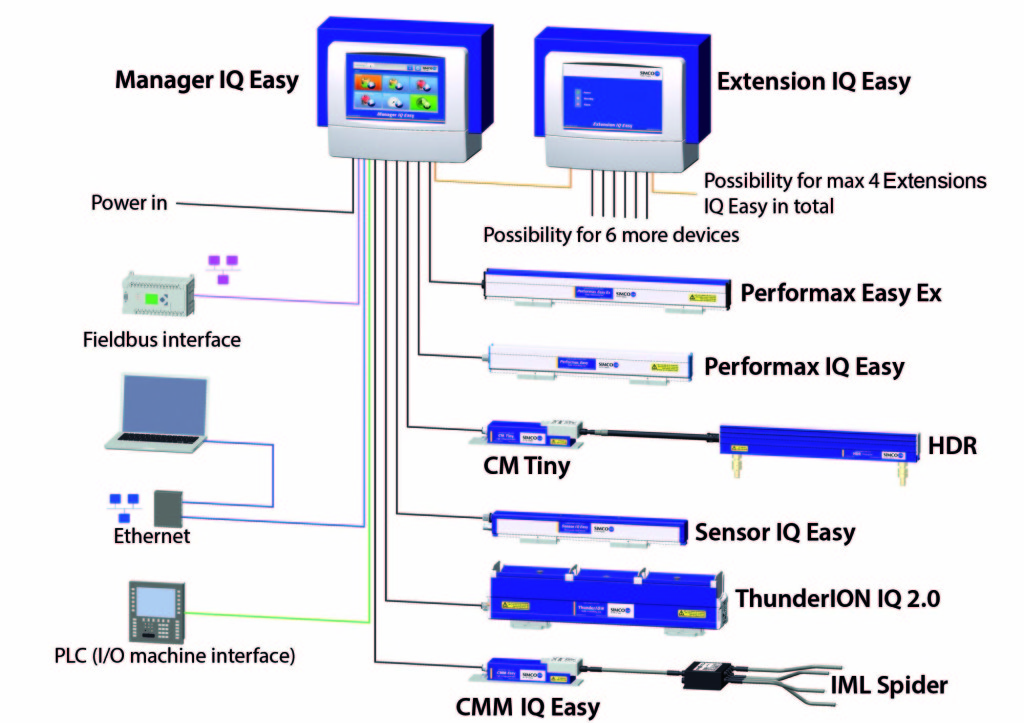

Simco-Ion’s new IQ Easy platform can control and monitor static charge levels through your production process and prevent defects and rejects.

The system combines static electricity sensors with ant-static bars to reach as low as possible residual charge levels and monitor the charge levels during various process steps.

A very low level of residual charge is achieved by a closed loop feedback circuit that enables the antistatic bar to adjust it’s efficiency depending on the measured down stream static charge level. Even at speeds higher than 1000 m/min the system reaches low charge levels which could never be accomplished with conventional antistatic bars.

Anti static bars Perfomax IQ Easy and Sensors IQ easy can be placed at strategical positions in your production process to ensure complete control during all production steps.

Data and actions will be logged for quality control and system evaluation.

Many high end customers have adapted the IQ Easy platform and implemented it to ensure consistent quality film to be delivered to their customers.

Interested?

Please contact Simco-Ion for more information, a demonstration or live test in your process.

Simco-Ion

Aalsvoort 74

7241MB Lochem

The Netherlands

0031573288333

www.simco-ion.nl