ETI Converting Equipment is a globally innovative manufacturer of in-line coating and printing equipment dedicated to the label printing industry

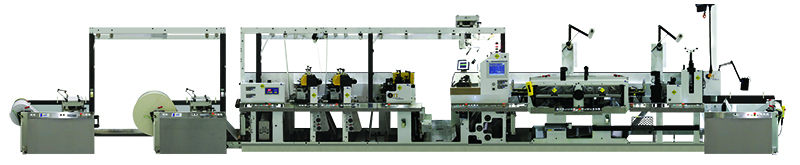

Compact and simple to use, an in-line coating and printing equipment named Cohesio converts any type of paper, board or film into self-adhesive material.

Two unwinds directs the facestock and the liner into the Cohesio line. During the process, the liner is coated with silicone and adhesive. Subsequently, the top material is joined with the liner to result in a pressure sensitive label stock.

Cohesio equipment can apply silicon and adhesive in full width or in any pattern, and can use different adhesives technologies: standard hotmelt, UV adhesive curable acrylic hotmelt and waterbased emulsion.

- Print first

Possibility to print under the silicone and adhesive (both side of face stock and both side of the liner) eliminates the waste of liner, adhesive and silicone and gives you the opportunity to reduce the cost of the product. None of our competitors will be able to achieve this cost reduction by converting raw materials

- In-line silicone & adhesive coating and lamination

Produce your own pressure sensitive material and take advantage to control the manufacturing processes of your PS materials, as well as increase your margin of profit by purchasing raw materials instead of pre-laminated label stock. Enlarge your capacity by producing multi-layer coupons, linerless products, labels with pattern silicone and adhesive application, labels on thin liner ( MiniLiner).

ETI Converting at LabelExpo Americas

ETI can’t wait to present an ultra compact version of Cohesio called Mini-Cohesio. This unique technology combines silicone, adhesive, lamination and die-cutting processes to produce self adhesive label stock all in line.

Mini-Cohesio uses less space, a shorter web path, is faster to set up and more affordable. This year, live at LabelExpo Americas, Mini-Cohesio will produce clear-on-clear PS labels supported by very thin liner at speed of 500ft/min (150m/min) in one manufacturing process. The equipment at the show will integrate printing, coating, die-cutting, and converting capabilities.

The machine is equipped with Pellicut, unique die-cutting system from ETI. This patented technology is compact, robust and extremely precise to die cut on .72mil (18mic) PET liner.

This innovative technology is ideal to convert pre-printed web into a finish label. Come to meet us at Booth 2040. We will have a demo each hour.

ETI Converting Equipment

Tel. : 1-450-641-7900

Fax : 1-450-641-7911

www.eticonverting.com