Listing Details

BALDWIN Vision Systems

Baldwin Vision Systems (BVS) designs and manufactures the industry’s most advanced color management and inspection technology solutions to help you achieve print quality perfection. By automating your workflows, we help you manage increasingly complex requirements and exacting standards. We enable you to dramatically reduce waste, prove your print quality, and reduce customer rebates…delivering a fast return on investment that will make a major impact on your bottom line.

Among the BVS automated solutions:

Color Measurement with DeltaCam™ delivers affordable, accurate inline spectral measurement to achieve absolute color consistency. Packaging converters can utilize automated, full spectral value measurement—in agreement with ISO standards—on film, paper, or board, ensuring that all printed products are within their customers’ color specifications.

Defender® 100% Inspection utilizes the industry’s most advanced defect detection algorithms to quickly classify each defect, driving better print quality decisions. Unique self-learning algorithms monitor the capabilities of the press and automatically apply optimum inspection tolerances to each job. Job settings can be quickly modified and saved. Manual fine-tuning makes it possible to reduce false or nuisance alarms by simply adjusting sensitivity levels for multiple defect types and different substrates. Modern, high efficiency, fan-cooled LED lighting delivers high intensity with greater image detail and low image noise.

Defender Data Central offers more intelligent print inspection by using the visual maps of each inspected roll. Quality control operators can analyze for defect distribution, count, and type. Out-of-tolerance areas are identified for removal, and job-based quality reports can be generated.

Defender Waste Manager can interface with rewinding, slitting, and sheeting equipment to automatically control when they stop/reject—allowing for fast and easy removal of defective material. Defect location data speeds up the converting process by allowing operators to fast-forward to the exact location of the defect within a roll.

For all the Defender components, powerful yet easy-to-use multi-touch interfaces require very little training to operate. New users can be trained on the app-style system in a few minutes and print operations can be less reliant on highly skilled operators.

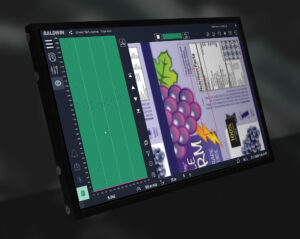

Guardian PQV advanced inspection is a feature-rich system that provides true 100 percent print inspection for pharmaceutical, converting, label, flexo, wide, and narrow web applications. At home on any press or slitter/rewinder, the system provides unparalleled power and accuracy through defect detection, OCR/OCV, bar code grading and verification, dimensional gauging and much more. Recent enhancements to the Guardian PQV include automated setup and automated job changeover—limiting operator intervention for a more efficient and accurate inspection process.

Guardian RTM is a new real-time quality monitoring and reporting tool for the Guardian PQV advanced print inspection system. Guardian RTM uses a central server to monitor, collect, and display real-time inspection data for multiple presses and jobs—and even across multiple plants—on a simple, uncluttered dashboard user interface. This data-connecting technology allows printers to track and compare many different production metrics. Press managers can monitor changes as they happen, and make highly-informed decisions about print quality, defect management, and even operator-to-operator performance. This is a unique competitive advantage, in that it’s truly the first product of its kind to tie together how you manage your processes, your print customers, and even your people. You’re empowered to quickly identify any mechanical issues, process inefficiencies, or even tailor your operator training to eliminate defects.

Guardian OLP PDF proofing and off-line inspection system can automatically find and highlight differences in print quality from an approved master image. The Guardian OLP can compare a one-up electronic file or scan to a multi-up electronic file or scan. This system will detect printing defects, such as missing or extra print, pre-press errors, plate defects and color variations.

Graphic-Vision® 500 Series web viewers are easy-to-use systems designed with industrial, high-performance parts. These systems feature long-lasting LED lighting, making them perfect for high-speed applications. The GV-530 offers advanced camera multi, programmed and combination positioning, in addition to automatic lateral and linear scanning.

Performance-proven Autotron is a highly robust, industry-renowned register system that enables packaging converters to offer increased print quality. With greater sensitivity and optimum control over register errors at every stage of the printing process, packaging converters achieve perfect register, reduced waste, and a solid return on investment. Autotron has been designed as a ‘plug and play’ system, requiring minimal installation time and operator training. The modernized system ensures a seamless transition for printers looking to benefit from the latest in print register technology.

The Vision Systems business unit of Baldwin Technology Company, Inc. unites former brands PC Industries, QuadTech, and Web Printing Controls into a print technology powerhouse—the world’s leading innovator of advanced color management and print inspection technology. Baldwin Vision Systems sells its automated control systems in more than 100 countries and maintains a worldwide network of sales and service operations.